FAQ HTG

Overview:

How can I find the suitable Thickness Gauge?

What is the difference between HTG-A, HTG-B, HTG-C and HTG modular?

Which material thickness can I measure?

How can I extend the measuring range of the gauges HTG-A and HTG-C?

How often the thickness gauge should be calibrated?

How can I avoid errors while measuring?

How can I find the suitable Thickness Gauge?

You can select a Thickness Gauge based on a specific standard, a specifiy material or foot diameter and weight/pressure.

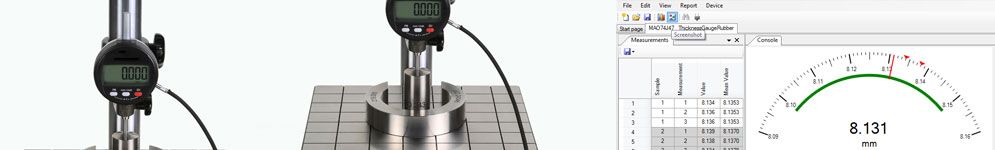

What is the difference between HTG-A, HTG-B, HTG-C and HTG modular?

We use the HTG-A up to a measuring weight of approx. 290 g. Is the measuring weight higher we use HTG-C. The HTG-B is intended for measuring foils. The gauge has a higher measuring accuracy combined with a smaller measuring way. At the HTG version you can select the foot and weight individually.

Which material thickness can I measure?

The gauge for HTG-A and HTG-C has a measuring way of 12 mm. Die gauge for HTG-B has a measuring way of 0,8 mm or 1,8 mm according to the selected resolution.

How can I extend the measuring range of the gauges HTG-A and HTG-C?

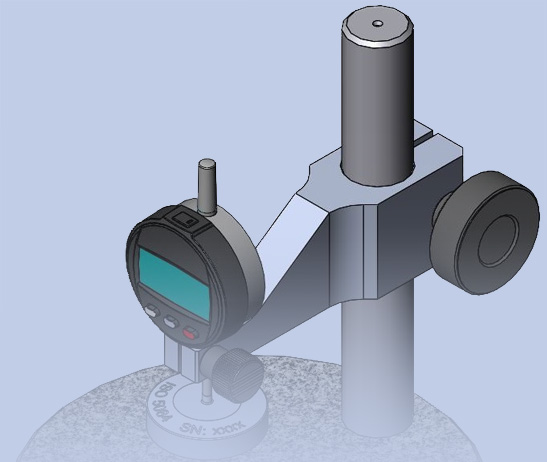

The measuring range can be extended with a slip block and the Preset-Function on the gauge (see video). The slip block (e.g. 10 mm) will be placed in between the granite base and the foot. With the Preset-Function of the gauge you can select the suitable height. Now you can measure parts between 10 mm and 22 mm.

How often the thickness gauge should be calibrated?

We recommend an annual calibration.

How can I avoid errors while measuring?

- Before measuring you have to check if the thickness gauge is suitable for the material and standard.

- The thickness gauge should be placed on a plane, rigid and shock-free surface.

- Avoid direct exposure to sunlight and draught.

- Clean before you start the measurement all surfaces that can affect the reading.

- Lower down the foot carefully onto the sample.

- The ambient temperature, the temperature of the sample and the gauge should be 23 °C.

- Don`t exceed the predefined material thickness.

- The measuring time must be observed.

- If you make more than one measurement per sample you can use the measuring position only one time.

- If the thickness gauge is used improper you have to check it or send it back for calibration.